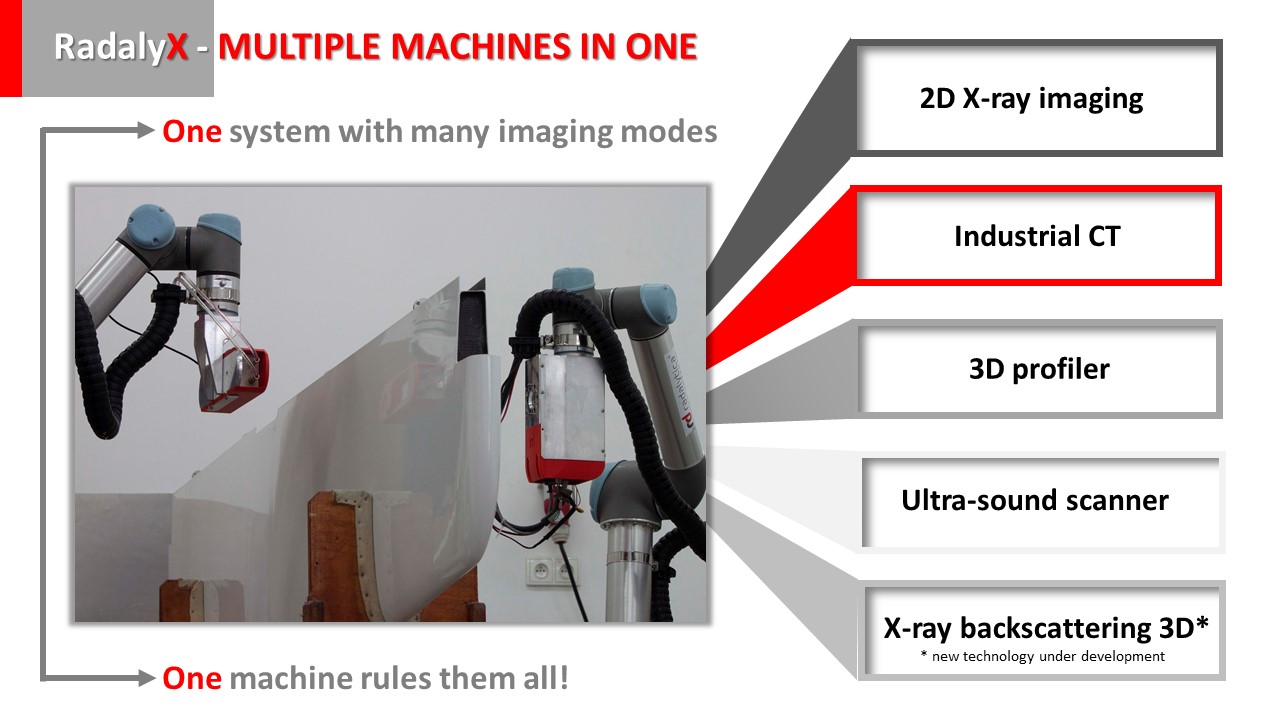

RadalyX - Robotic X-ray CT

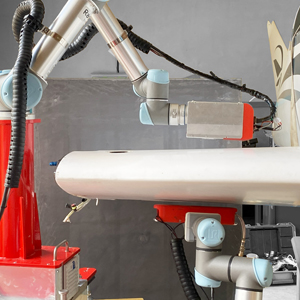

RadalyX is a cutting-edge robotic X-ray CT system that redefines imaging flexibility and precision. Equipped with two synchronized six-axis robotic arms—one holding an X-ray tube, the other a high-resolution detector—it moves freely around objects, capturing unparalleled detail from any angle. Unlike conventional scanners, RadalyX adapts seamlessly to complex shapes and sizes, making it ideal for inspecting advanced composite materials. Whether using X-rays or ultrasonic probes, this system delivers superior imaging for industries demanding the highest quality in non-destructive testing.

TECHNOLOGY APPROACH, WHICH SOLVES many of the issues associated with the conventional techniques.

Advantages of RadalyX

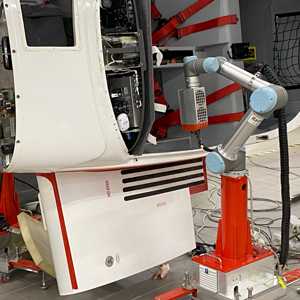

ENABLING ON-SITE INSPECTIONS IN HANGARS

THE MAJOR BENEFIT IS THAT THE SYSTEM CAN BE MOVED TO THE OBJECT TO BE INSPECTED.

This is in sharp contrast to common industrial CT systems where the sample has to fit inside. Our machine can get to the sample.

Modular combination of imaging methods

Modular combination of imaging methods Flexibility regarding size and shape of samples

Flexibility regarding size and shape of samples Stand-alone flexible lab systems or portable systems

Stand-alone flexible lab systems or portable systems Robots can also be installed in the fuselage of an aircraft

Robots can also be installed in the fuselage of an aircraft Possibility to integrate into production lines

Possibility to integrate into production lines